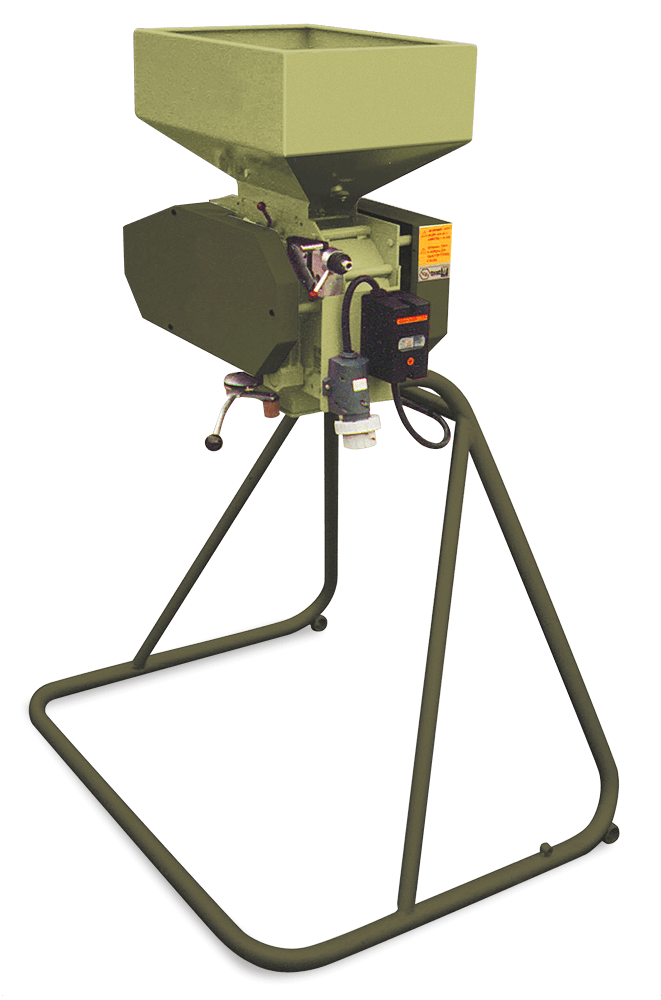

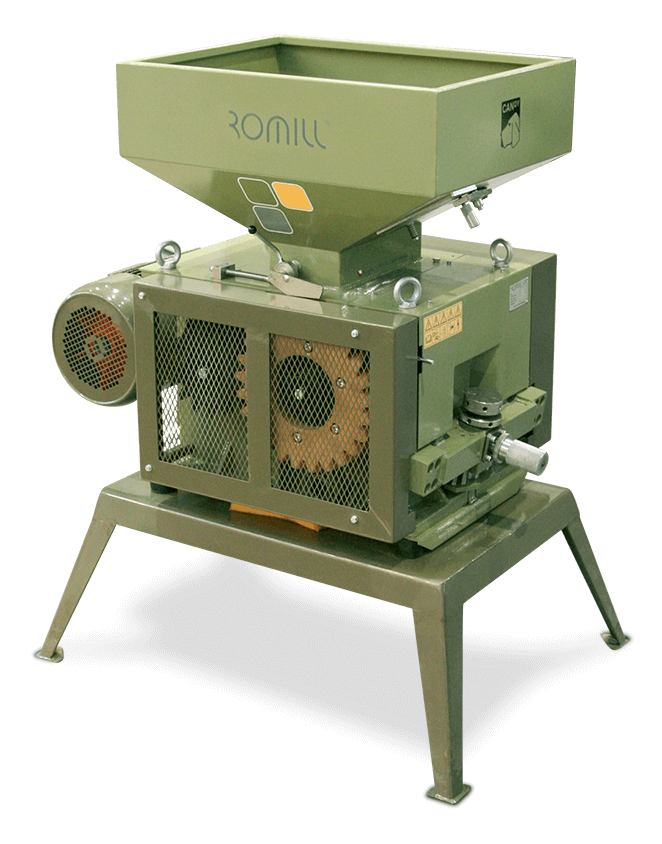

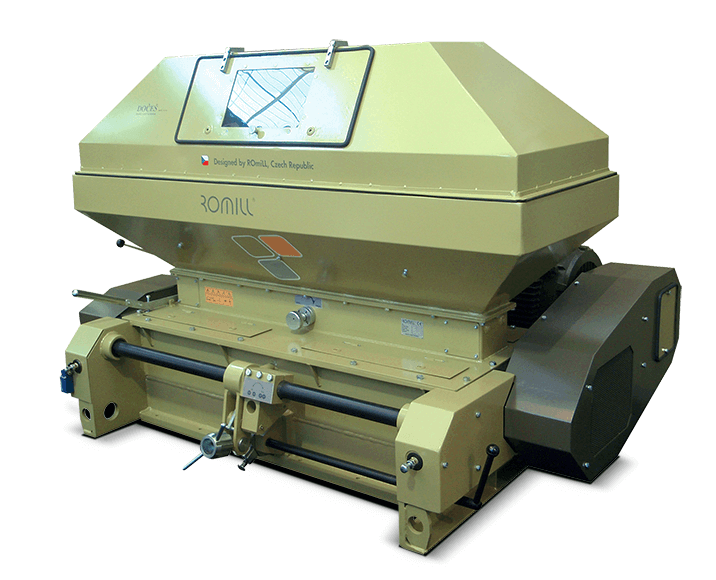

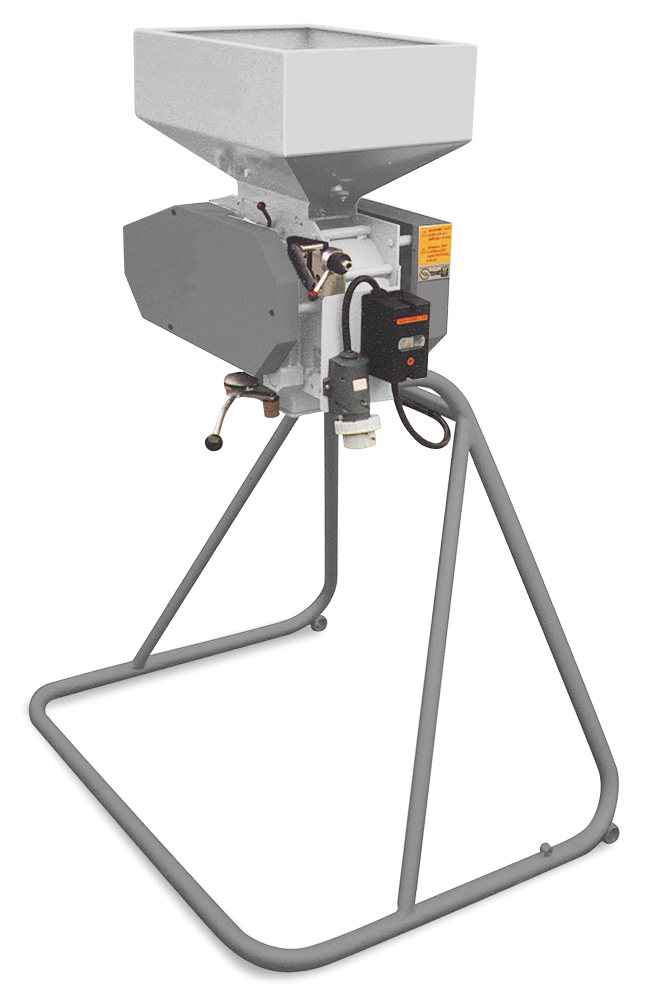

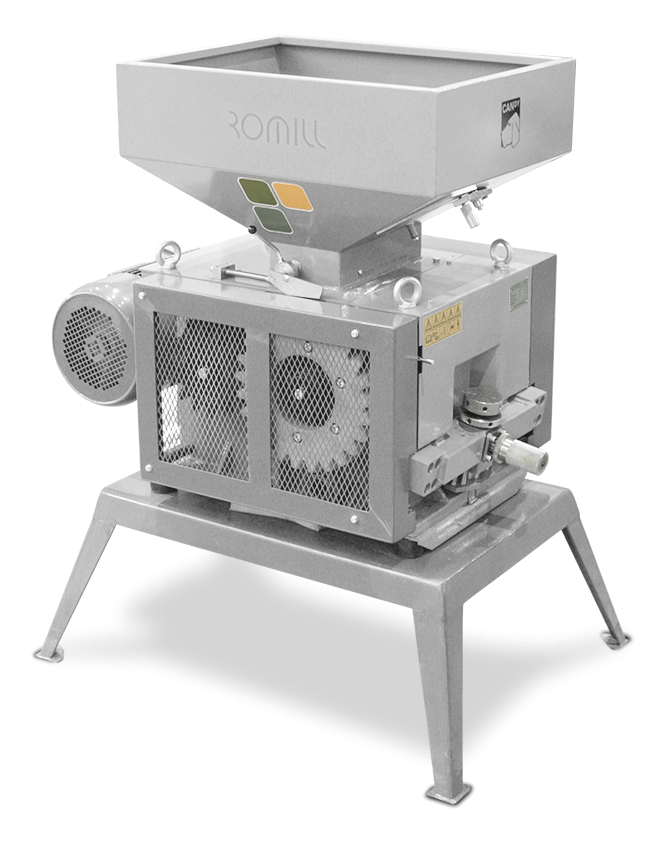

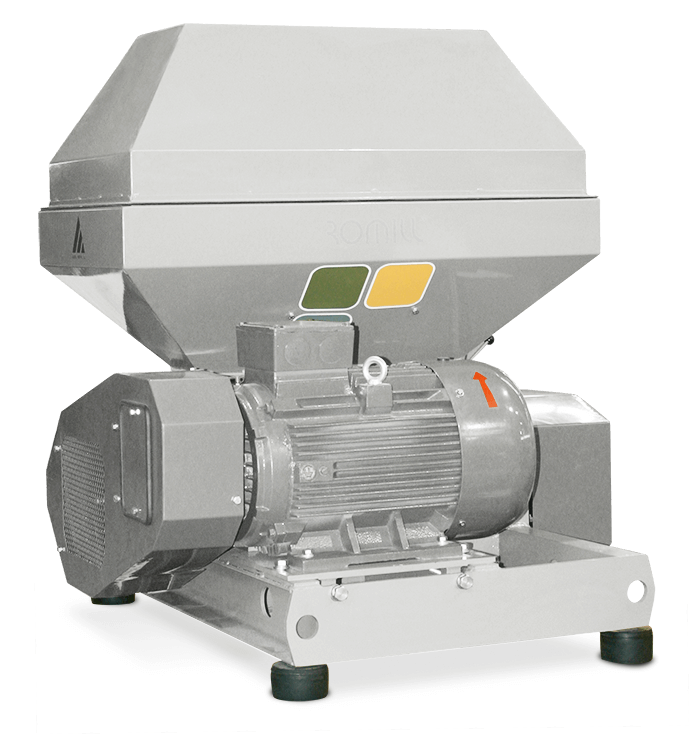

Stationary grinders, crimpers and crushers

An efficient method of processing feed materials

The feed value of processed material from ROmiLL roller grinders, crushers and crimpers increases the digestibility and production efficiency of feed. These machines are used for processing most feed materials – especially grains, legumes, oilseeds, etc. They can be used for processing both food and non-food production.

Robust design

The high hardness of the working rollers

The simple and quick setting of feed coarseness

The unique system of protection against damage

Are you interested in our products or do you need more information?

Contact